Introduction

Many reactions are truly reversible (see blog post Part 4) and, as a

consequence, substrate(s) and product(s) are in equilibrium with each other.

The position of this equilibrium depends on thermodynamics and process conditions.

This blog post will deal with equilibriums and how to shift them more towards

the product to allow you to isolate your product in an economic manner.

There are two main ways of shifting an equilibrium towards the product

side: push and pull. Let’s look at the example in Figure 1 (a) below. This is

an ester hydrolysis in hexane as solvent where the desired molecule is the

acid. Understandably, increasing the concentration of H2O (b) will

favor hydrolysis and the arrow in the forward reaction becomes bigger. I call

that ‘pushing’ the equilibrium. We could also ‘pull’ the equilibrium towards

the product by removing the methanol by evaporation (c). We could also do both

(d). See how the arrows change?

Alternatively, we could pull the acid from the reaction medium by

binding the acid at the right pH to an anion exchange resin[1], or make it

precipitate as a salt with an appropriate counter ion, for instance.

Figure 1: Example of a lactic acid ester hydrolysis.

I will now give a few examples of solving the equilibrium issues from

enzyme classes that if you follow my blog should be familiar to you.

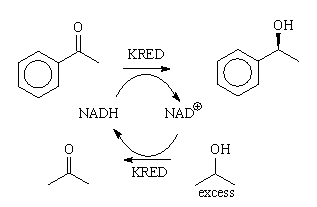

Ketoreductases

Ketone reductions are fully reversible reactions that lead to a

chemical equilibrium of ketone and alcohol (Figure 2).

Figure 2: The KRED catalyzed equilibrium reaction. [2]

If we would use a large excess of NADH, we might be able to push the

reaction to completion. However, the cost of NADH is too high to do that and,

also, high concentration of NADH acts as an inhibitor of many KREDs.

Economically, we can only use a little bit (a catalytic amount) and then only of

the cheapest form: NAD+. Therefore, the cofactor needs to be

recycled many times. This can be done by doing a similar reaction in reverse,

using a sacrificial alcohol as a co-substrate. Isopropanol (iPA) is often used

for this purpose. The scheme from Figure 2 changes to the one in Figure 3. Thus,

in the first step, the KRED oxidizes iPA to acetone and the NAD+ cofactor

is reduced to NADH. In the next step, the same KRED enzyme reduces the aryl ketone

to the chiral alcohol (hopefully) or it reduces acetone back to iPA (L).

Clearly, the efficiency of this system depends on the binding

affinities and turnover rates for iPA compared to aryl ketone. The aryl ketone

must bind better, but not so much better that it cannot be displaced by iPA

every now and then.

Figure 3: Formal scheme of KRED-catalyzed transfer hydrogenation.

Most people only use the simplified scheme shown in Figure 4 which only

becomes valid under a certain circumstance that I’ll get to in a moment. In the

mean time, note that the scheme in Figure 3 really does not have any

directional arrow. It is like the wheel of a car that can rotate in each

direction but if we want to go somewhere, it better rotate in the same

direction for a while! We need an external force that makes the wheel turn (clockwise

in this example).

That external force is created by adding a large excess of iPA: running

the enzymatic reaction in 50/50 water/iPA, or sometimes even up to 90% iPA [3]!

The large excess iPA pushes the equilibrium of the iPA oxidation all the way to

the acetone side, de facto making

that reaction uni-directional. Now, since that reaction now only goes in one

direction, the coupled reaction can also only go in one direction: towards the

chiral alcohol. We have created the scheme that is shown in Figure 4.

Figure 4: Simplied scheme for ketone reduction with excess iPA.

In some cases, the excess of iPA is not enough to push the desired

conversion above 99% yield [4, 5]. Removal of acetone by vacuum or a nitrogen

gas sweep helps pull the lower reaction to completion and thus the coupled

formation to chiral alcohol.[6] In some cases, precipitation of the chiral

alcohol can be achieved by tailoring the reaction medium; this is another case

of ‘pull’ [7].

The iPA/Acetone system is not perfect for every case: sometimes the

process conditions cannot be optimized to give adequate conversion, or the KRED

might not accept iPA as substrate. In those cases, a selection of different coupled

enzymatic reactions can be used [8]. Most popular are using glucose

dehydrogenase (GDH, [9]), formate dehydrogenase (FDH, [10]) and phosphite

dehydrogenase (PTDH, [11]) coupled systems. These reaction schemes are compiled

in Figure 5.

Figure 5: Three popular enzymatic cofactor regeneration systems.

What is important to remember in these multi-enzyme systems is that the

cofactor needs to shuttle back and forth from one enzyme to the other. This

shuttling is also something to keep in mind when KREDs are immobilized: the

fixation to the carrier must not interfere with substrate and product transport

as well as allow fast exchange of the cofactor which happens to be a rather

large molecule and (may) requires conformational changes in the protein. Apparently

it can be done since SPRIN in Italy offers a kit of 12 immobilized KREDs and

also has an immobilized GDH.[12]

Transaminases

Transaminases catalyze transfer of an amine group from a donor to a ketone and can use isopropyl amine (iPM) as amine donor, or use natural

amino acids like alanine as donor. See Figure 6 and 7 for iPM and Alanine,

respectively. Note that in these schemes, the recycle of the pyridoxal phosphate (PLP) cofactor is omitted for clarity.

Figure 6: ‘Chemical tricks’ to achieve better yield. Binding of the product-amine

to a resin also alleviates the product inhibition that is often seen with TAs.

Figure 7: Two enzymatically coupled reactions to drive transaminations

to completion. [15] And then I have not even shown another one using pyruvate

decarboxylase [16].

Haloalcohol dehalogenases

The ring closure of 1-(4-nitrophenyl)-2-bromo

ethan-1-ol (dubbed by a biochemist ‘PNSHH’ for para-nitrostyrene halo hydrin

and the name caught on...) to 4-nitro-styrene oxide (PNSO) and bromide ion was

scaled up. Reaction conditions: 15 gr substrate, 3 liters of 50% toluene/water

biphasic mixture and 100 g of acetate-loaded ion exchange resin that bound the released halide. We achieved

complete conversion with essentially absolute enantioselectivity .[17] Enzyme

load was 50 mg total and was provided by Ms Lixia Tang.

Figure 8: Since it was his idea, Jeffrey lutje Spelberg got to hold the flask in this picture which was later simply put in a shaker at 30°C.

Conclusions

Dealing with equilibrium reactions may seem daunting but as long as one

of the reactions in a coupled system is or can be made uni-directional, the

proof of concept has been made. Process optimization must follow and a rule of

thumb is “less enzyme is cheaper”. However, if using multiple enzymes can lead to a 100% yield and a simple product isolation, it can still be a winner.

References

[1] Resins available at scale, for instance, from www.purolite.com. Also look at their Purolite

LifeTech™ brand for biocatalysis and

life sciences applications.

[2] Of course this discussion does not mention NADP(H) as a cofactor

for simplicity.

[3] C Savile, JM Gruber, E Mundorff, GW Huisman, and SJ Collier. WO2010/025287

Ketoreductase polypeptides for the production of 3-aryl-3-hydroxypropanamine

from a 3-aryl-3-ketopropanamine. Patent granted to Codexis. Example 9 shows

conversion of a ketone on preparative scale at 90% iPA.

[4] J Liang, E Mundorff, R Voladri,

S Jenne, L Gilson, A Conway,

A Krebber, J Wong, GW Huisman, S Truesdell, and J Lalonde.

Highly Enantioselective Reduction of a Small Heterocyclic Ketone: Biocatalytic

Reduction of Tetrahydrothiophene-3-one to the Corresponding (R)-Alcohol. Org.

Process Res. Dev., 2010, 14 (1), pp 188–192.

[5] From an atom utilization standpoint, using ‘excess’ of something is

less elegant and frowned upon according to the 12 principles of Green Chemistry:

http://www.epa.gov/sciencematters/june2011/principles.htm

. Use of excess reagents should be avoided where possible.

[6] SJ Calvin, D Mangan, I Miskelly, TS Moody, and PJ Stevenson.

Overcoming Equilibrium Issues with Carbonyl Reductase Enzymes. Org. Process

Res. Dev. 2012, 16, 82–86. http://www.almacgroup.com/wp-content/uploads/Overcoming-Equilibrium-Issues-with-Carbonyl-Reductase-Enzymes.pdf

[7] J Liang, J Lalonde, B Borup, V Mitchell, E Mundorff, N Trinh, DA

Kochrekar, RN Cherat, and GG Pai. Development of a Biocatalytic Process as an

Alternative to the (−)-DIP-Cl-Mediated Asymmetric Reduction of a Key

Intermediate of Montelukast. Org. Process Res. Dev., 2010, 14 (1), pp 193–198.

[8] A very nice range of cofactor recycling enzymes can be acquired

from Evocatal in Germany. http://www.evocatal.com/en/products/evozymes/cofactor-regeneration.html.

Industrial scale quantities of GDH can be acquired from Codexis. FDH has decreased

in popularity because of lack of robustness under process conditions although

it was the basis for Degussa’s process for tert-Leucine. PTDH is still

experimental.

[9] See reference 4, but there are many other examples.

[10] Pioneering work was done by my friend Vladimir Tishkov from

Lomonosov University in Moscow to engineer NADP specificity in an NAD-dependent

FDH and reviewed in a nice overview: http://www.enzyme.chem.msu.ru/~tishkov/Publications/Proteins_19_FDH.pdf

[11] TW Johannes, RD

Woodyer, H Zhao. Efficient Regeneration of NADPH Using an Engineered Phosphite

Dehydrogenase. Biotech. Bioeng. 2007, 96 (1), pp 18-26. http://scs.illinois.edu/~zhaogrp/publications/HZ53.pdf

and also their nice review of cofactor recycle systems: http://www.scs.illinois.edu/~zhaogrp/publications/HZ21.pdf

[12] http://www.sprintechnologies.com

or through their US distributor: http://www.itochu-purification.com/products/biocatalysis/new-immobilized-ketoreductases

[13] K Engelmark Cassimjee, C Branneby, V Abedi, A Wells, and P Berglund.

Transaminations with isopropyl amine: equilibrium displacement with yeast

alcohol dehydrogenase coupled to in situ cofactor regeneration. Chem. Commun.,

2010, 46, pp 5569-5571.

[14] MD Truppo, JD Rozzell, and NJ Turner. Efficient Production of

Enantiomerically Pure Chiral Amines at Concentrations of 50 g/L Using

Transaminases .Organic Process Research & Development 2010, 14(1), pp.

234-237.

[15] MD Truppo, JD Rozzell, JC Moore, and NJ Turner. Rapid screening

and scale-up of transaminase catalysed reactions. Org. Biomol. Chem. 2009, 7, pp

395-398.

[16]M Höhne, S Kühl, K Robins, UT Bornscheuer. Efficient Asymmetric Synthesis of Chiral Amines by Combining

Transaminase and Pyruvate Decarboxylase. ChemBioChem 2008, 9(3), pp 363–365.

[17] JH lutje Spelberg, LX Tang, EJ de

Vries, RM Kellogg, and DB Janssen. Biocatalytic preparation of

optically pure epoxides and derivatives. Poster presentation at Biotrans 2003,

Olomouc/CZ.